HEALTHCARE CONSTRUCTION

- HEALTHCARE CONSTRUCTION OVERVIEW

- CASE STUDIES

- COMPARING AIRFLOW RATINGS

- AIR CHANGE CALCULATOR

- CUSTOMER TESTIMONIALS

- DUST CONTAINMENT MODULES

- FACTS ABOUT HEPA FILTRATION

- FAQS

- PRINCIPLES AND IMPORTANCE OF NEGATIVE PRESSURE CONTAINMENT

- MODES OF OPERATION

- THE IMPORTANCE OF CONDUCTING A COMPREHENSIVE ICRA

- LINKS & ARTICLES

- NRTL SAFETY CERTIFICATION

- PRODUCT SELECTION & APPLICATION ASSISTANCE

- UL94HB FLAMMABILITY REQUIREMENTS

HEALTHCARE CONSTRUCTION

TAKE EFFECTIVE INFECTION CONTROL MEASURES BY ISOLATING AND CONTAINING PARTICLES RELEASED INTO THE AIR DURING HEALTHCARE CONSTRUCTION, RENOVATION & REPAIR ACTIVITIES

Abatement Technologies® high-efficiency, HEPA-filtered Portable Air Scrubbers, Mobile Containment Barriers and Additional Particle Control Products are used to effectively isolate, capture and control airborne dust particles and pathogens. Our cost-effective, time-saving products are used by contractors and maintenance departments in thousands of healthcare facilities to protect sensitive patients and employees from exposure to construction particles that can potentially transmit airborne infectious diseases. Abatement Technologies particle control products also increase productivity and reduce the cleanup time during and after projects.

Abatement's team of highly-trained and experienced healthcare specialists can help you select the appropriate HEPA-filter devices for your application to help reduce exposure to airborne pathogens associated with hospital-acquired infections. Learn how our state-of-the-art systems and controls can help create a healthier indoor environment.

CASE STUDIES

Read how customers in hospital and healthcare facilities use Portable Air Scrubbers from Abatement Technologies® for renovation and construction activities.

MEETING THE JOINT COMMISSION STANDARDS FOR PATIENT CARE

Adventist Health–Portland, OR

The Joint Commission guidelines state that high-risk immunosuppressed patients must be protected from Aspergillus-containing dust particles that may be released during construction and remodeling projects. Adventist Health in Portland, OR utilizes Abatement portable air scrubbers to capture and remove harmful spores during construction and renovation activities.

The PAS machines are:

- Portable-Upright design profile with built-in transport dollies and soft rubber tires make it easy to move to projects

- Quiet-Quiet operation enables use in almost all areas without affecting surroundings

- Durable-Aircraft-type construction provides many years of on the job use with minimal maintenance or downtime

Read how Abatement Technologies HEPA-AIRE Portable Air Scrubbers help Adventist Health stay within AIA guidelines for infection control.

CEILING WORK REQUIRES NEGATIVE PRESSURE

St. Joseph’s Hospital and Medical Center–Phoenix, AZ

St. Joseph’s Hospital and Medical Center in Phoenix, AZ uses 14 Abatement portable air scrubbers for all types of construction and renovation projects. The machines are especially put to work when performing maintenance or small projects in ceilings, such as replacing fluorescent light bulbs or pulling cable.

The unit is tied into the ceiling to create negative pressure while a smoke stick is used to verify airflow direction. The unit allows work to be performed without compromising the surroundings.

Features include:

- Powerful Performance-Motors and blowers are designed to provide powerful airflow

- User-Friendly-Recessed controls are reliable and easy-to-use

- Easy-to-Clean-Cabinets are easy to clean and decontaminate

Learn more about the use of Abatement portable air scrubbers in ceiling maintenance work at St. Joseph’s Hospital.

WHY AIRFLOW RATINGS CAN BE MISLEADING

NO INDUSTRY-STANDARD AIRFLOW RATING METHOD

There is no standardized method that manufacturers use to rate the airflow of their air filtration devices. Different methods can produce widely varying and often misleading results, and make direct comparisons between brands difficult if not impossible.

Comparing ‘Apples & Oranges’

Ratings The most overstated and inaccurate method used bases device airflow ratings on the AMCA “free air” blower rating, which is a test bench measurement of the airflow the blower can produce at various motor horsepower levels with no static resistance. Since actual peak airflow with the cabinet and filters in place is typically 50% to 80% lower, free air is essentially meaningless when it comes to rating the device itself.

Inlet or outlet readings with an air-straightening duct attached to reduce turbulence are far more accurate. This testing is generally done using a computing vane anemometer or pitot tube traverse to determine the average velocity (in feet per minute) and airflow (in cubic feet per minute) flowing through the air straightening duct. Attempting to measure airflow at non-laminar inlet and outlet openings is not recommended.

Peak Airflow Is Only Part Of The Story

Even when accurate, peak airflows can be misleading because they provide only a small part of the performance picture. It's often a mistake to automatically conclude that the performances of two devices are equal just because their peak airflows are similar. The airflow of all filtration devices drop off as resistance to airflow increases due to filter loading, external collars or flex duct. The magnitude and frequency of these losses; and therefore how frequently filters must be replaced to restore acceptable airflow levels can vary greatly.

Peak static capacity of the blower and filter dirt holding capacity are the main factors that determine 'real life' airflow and filter life. As a rule, a backward curved blower can move more air than a cheaper but less efficient squirrel-cage blower, due largely to its ability to operate at much higher 'tip speeds' and therefore overcome higher levels of resistance. This higher capacity, in turn, extends the useful life of the filters and can make a higher price but more efficient system far less costly to operate.

Build In A Sufficient Margin of Safety

To compensate for airflow losses, users should build in a safety margin when estimating how many units are required to provide a given number of ACH (air changes per hour). If the objective is 6 ACH, designing for 8 or 9 ACH at peak airflow should be more than adequate to ensure sufficient airflow throughout the filter loading cycle provided that the peak airflow rating is reasonably accurate.

Air Change Calculator for Abatement and Remediation

CUSTOMER TESTIMONIALS

Read what healthcare customers have to say about using Abatement Technologies® Portable Air Scrubbers in construction and renovation projects.

Methodist Hospital of Southern California,

Arcadia, CA

“Methodist Hospital has used the Abatement portable air scrubber for numerous projects.

It has really come in handy with our current renovation for a new minimal invasive surgery suite. This machine removes all dust and odors and creates a negative pressure for our infection control

issues for JCAHO. I highly recommend this machine for any healthcare institution

that has any construction, renovation or painting projects!”

– R.D., Director of Facilities,

Appleton Medical Center,

Appleton, WI

“We have successfully used our PAS2000HC portable air scrubber during construction projects without any patient or staff complaints. This unit, coupled with the ZipWall temporary construction barrier, removes sheetrock dust, sanding/cutting dust and paint/welding fumes (with carbon filter installed). It’s easy to set-up and maintain. Definitely worth the investment.”

– E.C., Facilities Management,

Saint Patrick Hospital and Health Sciences Center,

Missoula, MT

“We used the Abatement PAS to remodel a cancer center where it was necessary to continue patient care while completing the project. The equipment was utilized to keep the work areas under negative pressure. The patients going through radiation therapy have reduced immunity and can’t afford to be exposed to construction work. The project was very successful and the equipment worked very well. It was quiet enough not to impact patient care or staff on the project and worked well with no failures.”

– B.M., Director of Engineering,

T.H. Marsh Construction Co.,

Royal Oak, MI

“Other contractors around us are using equipment that is less sturdy, harder to move around and more expensive. The AIRE GUARDIAN® is easy to set-up, meets ICRA requirements and we can work at multiple locations above the ceiling in the same day. I think it’s the best available and Abatement Technologies has great customer service!”

– D. G., Safety Director,

USING AIRE GUARDIAN® MOBILE DUST CONTAINMENT MODULES TO EFFECTIVELY MEET CDC AND ICRA CONSTRUCTION GUIDELINES

The Joint Commission-enforced Centers for Disease Control and Prevention Guidelines for Infection Control in Health-Care Facilities require the completion of an Infection Control Risk Assessment (ICRA) for all construction, renovation, repair, and maintenance activities. The ICRA provides a structured method for evaluating the risks of exposing sensitive patients to Aspergillus and other infectious microbes common in indoor environments that can attach to dust and dirt and other particles released into the air during the work, and determining suitable protective measures.

WHAT IS NEGATIVE PRESSURE PARTICLE CONTAINMENT?

The ICRA may indicate that protecting patients from exposure to airborne particles requires implementation of full negative pressure containment, which requires:

(1) Placing physical barriers around a work area that may generate airborne contaminants to separate or “segment” that area from the facility environment

(2) Continuously operating portable HEPA filtration devices known as portable air scrubbers to significantly reduce airborne particle counts within that area, and

(3) Exhausting a sufficient amount of HEPA-filtered air from the enclosure to create and maintain negative (lower) pressure compared to adjacent spaces

The objective is to find a way to effectively implement these protective measures in the most time-efficient and cost effective manner possible.

UNIQUE CONTAINMENT ISSUES FOR WALL & CEILING WORK

Infectious particles can thrive in ceiling and wall cavities thanks to near-optimal environmental conditions and an abundant supply of dirt, dust, and cellulose-based building material particles as food sources. Hospital construction and renovation activities in hospitals frequently require access to these spaces. Some typical examples of these types of activities include:

- Installing or removing wiring, network cabling, conduit or pneumatic systems above drop ceilings or in wall cavities

- Testing smoke detectors and other equipment

- Removing ceiling tiles or sheet rock to access plumbing and cabling networks or fluorescent lighting fixtures

- Installing, removing, replacing or servicing ceiling or wall mounted equipment or fixtures

The time and labor cost required to erect, dismantle and relocate a fixed barrier every time a ladder is moved from one ceiling grid opening to another make them an impractical particle containment solution for these types of jobs.

INTRODUCTION OF MOBILE CONTAINMENT BARRIERS

Prefabricated mobile construction containment modules sometimes referred to as ‘dust cubes’ or ‘dust carts’ have proven to be a more efficient alternative solution for this type of work. These portable devices can be rolled from one location in a facility to another and adjusted to accommodate various ceiling heights. There are two types of mobile containment products available today.

Facts About True HEPA Filtration

According to CDC Guidelines for Environmental Infection Control in Healthcare Facilities, HEPA filtration is required for the capture of microbial spores and other contaminants that can potentially cause fungal infections and Aspergillosis. All PREDATOR® and HEPA-AIRE® Portable Air Scrubbers are equipped with high-efficiency, HEPA filters that are tested and certified to remove at least 99.97% (9,997 out of 10,000) of particles 0.3 microns (0.000012-inch) in size. To put this in perspective, fungal spores are typically five to 25 microns in size.

TESTING AND CERTIFICATION BY INDEPENDENT NATIONAL LABORATORIES

Abatement HEPA filters meet the Institute of Environmental Sciences and Technology standard for Type A 99.97% efficiency HEPA filters. To meet this standard, each and every completed Abatement HEPA filter must be tested for leakage and resistance, to detect any leaks in the media or between the media and the frame or other problems that can compromise the integrity of the completed filter. Test results must be shown on a label on the filter frame. Abatement filter frames are metal or plastic. The CDC Guidelines state that: “Wood can compromise the air quality if it becomes and remain wet, allowing the growth of fungi and bacteria.” Abatement filters also meet UL900 flammability requirements.

HOW OFTEN DO ABATEMENT HEPA FILTERS NEED TO BE CHANGED?

The size and concentration of airborne contaminants, temperature, humidity conditions and duration of use determine how often filters need replacement. As the filters become loaded with particulate matter, the airflow capacity of the unit decreases and the static pressure differential across the filter increases.

Abatement PREDATOR and HEPA-AIRE Portable Air Scrubbers are equipped with easy-to-read filter change indicator lamps that illuminate when filters should be replaced. Unlike gauges, these lamps do not require operator interpretation or calculations. Average filter life (with continuous operation):

- Primary filter: 1 day

- Secondary filters: 3-7 days

- HEPA filter: 500 to 1,000 hours

WHAT ARE THE TOTAL COST-SAVINGS OF USING ABATEMENT PORTABLE AIR SCRUBBERS AND HEPA FILTERS VERSUS THE COMPETITION?

Abatement Portable Air Scrubbers and high-efficiency HEPA filters can potentially save users up to $10,000 or more over the life of the unit compared to other systems, including low-priced (and generally low-quality) “economy” products. By any measure, this is an excellent return on investment. Four main factors contribute to these savings:

1) Longer filter life because the filters provide exceptional dirt-holding capacity

2) Lower replacement filter costs

3) Lower labor costs due to higher productivity

4) Minimal downtime

WHAT DOES THE TERM HEPA MEAN?

HEPA is an acronym for "High Efficiency Particulate Air" or "High Efficiency Particulate Arrestance." This acronym refers to a filter that is manufactured, tested and certified to meet Institute of Environmental Sciences and Technology (IEST) construction, performance and certification standards as currently published in IEST RP-CC001.4.

WHAT IS IT THAT MAKES HEPA FILTERS SO EFFICIENT?

The ultra-fine, glass-fiber medium captures microscopic particles that can easily pass through other filters by a combination of diffusion, interception and inertial impaction. To qualify as a Type A HEPA filter, the filter must capture at least 99.97% (9,997 out of 10,000) of particles 0.3 microns in size–about 300 times smaller than the diameter of a human hair, and 25 to 50 times smaller than we can see. To a HEPA filter, catching a one-micron particle (1/1,000,000 of a meter) is like stopping a cotton ball with a door screen.

ARE ALL FILTERS MADE WITH HEPA FILTER MEDIA HEPA FILTERS?

No. Manufacturing a filter with HEPA filter media does not mean that the filter itself meets true HEPA efficiency requirements. Serious filter leakage can go undetected if filters are not individually tested and certified at the end of the manufacturing process. Even the tiniest pinhole leaks in the media or breach of the seal between the media pack and the filter frame can cause the filter to fail IEST requirements. The testing requires very specific procedures using a thermally generated mono-dispersed aerosol and a laser particle counter. Some regulations also require field-testing by the user prior to going into service and periodically thereafter.

WHY IS THE TESTING DONE WITH A 0.3-MICRON PARTICLE SIZE TEST AEROSOL?

Filter efficiency studies have shown that 0.3-microns is predominately the "Most Penetrating Particle Size (MPPS)" for HEPA filter media. Efficiency is typically greater than 99.97% against larger or smaller particle sizes. Particles larger than 0.3 microns are typically more easily trapped or intercepted, by the media. Smaller particles often lack sufficient mass to penetrate the media.

IS A "HEPA-TYPE" FILTER THE SAME AS A HEPA FILTER?

No. In fact, the differences are huge. According to the American Lung Association, filters classified as "HEPA-type" filters may capture as little as 55% of 0.3-micron particles (5,500 out of 10,000). By this definition, the true HEPA filter could be more than 1,800 times as efficient as the "HEPA-type" filter.

DOES HEPA FILTER EFFICIENCY DECREASE AS THE FILTER GETS DIRTY?

No. Filter media with an electrostatic charge and other air purification technologies can experience substantial loss of efficiency as they become dirty. Exactly the opposite typically happens with HEPA filters. The dirtier it gets, the more efficient it can become.

Abatement Technologies stocks a complete inventory of replacement filters, flex duct, collars and other accessories and additional products for same or next day shipment. Contact Us or call us to receive filter pricing and availability information.

FAQs about Equipment for Facility Construction and Renovation

Frequently Asked Questions about Abatement Technologies® Portable Air Scrubbers (PAS) for Removing Airborne Particles in Healthcare Settings

WHY IS NEGATIVE PRESSURE IMPORTANT TO CONSTRUCTION PROJECTS?

A negative pressure environment will help to contain the construction dust and contaminants within the construction space. A negative pressure space eliminates the possibility of contaminants passing outside of the construction area through leaks in the construction barriers.

HOW DO I CREATE A NEGATIVE PRESSURE ENVIRONMENT USING ABATEMENT PREDATOR® AND HEPA-AIRE® PORTABLE AIR SCRUBBERS?

In order to create a negative pressure environment, more air must leave the space than enters it. First of all, the construction area must be walled off with Abatement Technologies Containment Barriers. Secondly, the Abatement Portable Air Scrubber(s) must be placed inside the construction area. Ductwork should be run from the system to somewhere outside of the construction area, preferably to the outside of the building. Since the air is HEPA filtered, it is not mandatory to exhaust air to the outdoors.

WHICH SIZE ABATEMENT PORTABLE AIR SCRUBBER IS NEEDED FOR MY CURRENT PROJECT?

Six or more air changes per hour (ACH) are recommended for effective air cleaning during construction and renovation work. To determine the amount of airflow and the number of PREDATOR or HEPA-AIRE PAS units required for your project, view the air change calculator for facility construction and renovation projects in healthcare facilities.

HOW IS THE AMOUNT OF AIRFLOW THAT MUST BE REMOVED FROM THE CONTAINMENT ZONE TO MAINTAIN NEGATIVE PRESSURE CALCULATED?

The general rule of thumb is that at least 10% more air must be exhausted from the area than is supplied to it. For example, if 500 CFM is coming in through the facility HVAC system, then at least 550 CFM must be filtered and exhausted by the PAS.

WHY DO I NEED TO MONITOR ROOM PRESSURE WHERE I AM REMOVING AIRBORNE PARTICLES, ODORS AND INFECTIOUS DISEASES?

Air flows from a higher pressure to a lower pressure. The PREDATOR or HEPA-AIRE PAS creates a negative pressure in the room so that airborne particulates are pulled towards it and filtered out. The negative pressure prevents particulates from leaving the room you want to cleanse and contaminating adjacent areas. Room pressure differences must be monitored and maintained to be effective. The most reliable and sure way to confirm that pressure relationships are correct is to continuously monitor differential pressure using Abatement’s PPM3-S Portable Differential Pressure Monitor.

WHAT IF WE DON'T/CAN'T EXHAUST THE FILTERED AIR TO THE OUTSIDE?

Since Abatement Technologies Portable Air Scrubbers pull the air through a true HEPA filter tested and certified to a minimum efficiency of 99.97% @ 0.3 microns before it is exhausted from the containment space, there is no requirement that they be exhausted to the outdoors.

WILL THE ABATEMENT PREDATOR AND HEPA-AIRE PORTABLE AIR SCRUBBERS REMOVE ODORS?

Yes, when equipped with special 2-inch deep VAPOR-LOCK® carbon filters available for all PREDATOR and HEPA-AIRE PAS models. These high-performance filters provide substantially more absorption capacity than most other carbon filters and meet most odor control requirements. Special carbon blends are also available for capturing odors from low molecular weight compounds for which carbon has limited effectiveness.

WHICH PARTICULATES CAN ABATEMENT PORTABLE AIR SCRUBBERS CAPTURE?

All models (PREDATOR and HEPA-AIRE) are equipped with HEPA filters that are tested and certified to remove 99.97% of particles that are 0.3 microns and larger, to provide "operating room clean" filtered air. To put this in perspective, the diameter of a human hair is 50 to 200 microns, and fungal spores are typically five to 25 microns. For a complete list of particulate contaminants and odors that the Portable Air Scrubber can remove, please Contact Us with your fax number.

WHY IS HEPA FILTRATION REQUIRED DURING CONSTRUCTION AND RENOVATION PROJECTS?

According to the latest 2003 CDC Guidelines for Environmental Infection Control in Health-Care Facilities HEPA filtration is required for the capture of microbial spores and other contaminants that can potentially cause fungal infections and Aspergillosis. Airborne bacteria and fungi are typically 3 microns (0.0001”) and smaller in size, small enough to easily pass through most filters. Air filtration devices must, therefore, be equipped with true HEPA (High-Efficiency Particulate Air) filters, designed to capture at least 99.97% (9,997 out of 10,000) particles as small as 0.3 microns (0.00001”) in size.

ARE THERE ANY SPECIAL REQUIREMENTS FOR HEPA FILTERS USED IN HEALTHCARE FACILITIES?

Yes. To meet Institute of Environmental Sciences and Technology IEST-RP-CC001.3 standards for Type A 99.97% efficiency HEPA filters, each and every completed filter must be individually tested for leakage and resistance, to detect any leaks in the media or between the media and the frame or other problems that can compromise the integrity of the completed filter. Test results must be shown on a label on the filter frame. Filter frames should be metal. The 2003 CDC Guidelines state that: “Wood (HEPA frames) can compromise the air quality if it becomes and remains wet, allowing the growth of fungi and bacteria,” and recommends replacing these filters with metal-frame filters. Filters should also meet UL900 Class II flammability requirements.

WHAT ARE THE DIFFERENCES BETWEEN ABATEMENT PORTABLE AIR SCRUBBERS AND NEGATIVE AIR MACHINES?

We manufacture both types of products. Although they perform similar functions, they have distinctly different designs and markets. Big, boxy and heavy negative air machines with ‘no frills’ designs and hard casters are lower priced, but are best suited for large projects in unoccupied facilities. Abatement PAS have a much lighter weight, upright design that makes them much more portable and easy to roll into and maneuver through tight spaces with minimal disruption to an occupied facility. Higher performance motors, blowers and filtration systems substantially improve airflow output and filter life and reduce operating costs. More elaborate controls and high tech stainless steel cabinets that look great and are easy to clean add to their ‘hospital friendliness’. Learn more about Abatement Technologies line of high-performance PREDATOR and HEPA-AIRE Series Portable Air Scrubbers.

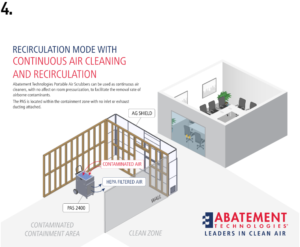

CAN ABATEMENT PORTABLE AIR SCRUBBERS ALSO BE USED TO FILTER AND RECIRCULATE AIR OR FOR POSITIVE PRESSURE?

Definitely. Abatement PAS units can be used to continuously filter and recirculate 100% of the filtered air within the construction area. This will boost the ACH in the room and provide HEPA filtration, but will not change room pressurization. All models can also be configured to create positive pressure.

DOES ABATEMENT TECHNOLOGIES OFFER ANY SOLUTIONS FOR CAPTURING AND REMOVING PARTICLES THAT DROP OUT OF THE AIR AND LAND ON WALLS, FLOORS AND OTHER SURFACES?

Yes. Surfaces should be frequently cleaned with a HEPA vacuum to further reduce the chance that harmful particles could migrate out of the area and become airborne again. Abatement Technologies offers two HEPA vacuum models, the V8000WD Canister Style, Wet/Dry HEPA Vac and the V1300H Hip-Mounted HEPA Vac.

HOW OFTEN DO ABATEMENT HEPA FILTERS NEED TO BE CHANGED?

The size and concentration of airborne contaminants, temperature, humidity conditions and duration of use determine how often filters need replacement. As the filters become loaded with particulate matter, the airflow capacity of the unit decreases and the static pressure differential across the filter increases.

Abatement Portable Air Scrubbers are equipped with easy-to-read filter change indicator lamps that illuminate when filters should be replaced. Unlike gauges, these lamps do not require operator interpretation or calculations. Average filter life (with continuous operation):

- Primary filter: 1 day

- Secondary filters: 3-7 days

- HEPA filter: 800 hours

WHAT ARE THE TOTAL COST-SAVINGS OF USING ABATEMENT PAS VERSUS THE COMPETITION?

Abatement PAS can potentially save users up to $10,000 or more over the life of the unit compared to other systems, including low-priced (and generally low-quality) “economy” products. Four main factors contribute to these savings:

- Longer filter life because the filters provide exceptional dirt-holding capacity

- Lower replacement filter costs

- Lower labor costs due to higher productivity

- Minimal downtime. By any measure, this is an excellent return on investment.

What does Abatement mean by “aircraft-type construction”?

Our stainless steel units are manufactured using solid rivet construction, for the same reasons aircraft manufacturers use them–solid rivets are exceptionally strong, durable and leak-resistant. In addition, closed-cell neoprene gaskets between the two layers of metal further ensure that critical seams are airtight. Sheet metal screw, hollow pop rivets, or nuts and bolts are far cheaper, but they are also far more prone to failure and leakage. Would you want to fly on an airplane made that way?

What Abatement accessories are needed for negative pressure applications?

PREDATOR and HEPA-AIRE Portable Air Scrubbers include an exhaust collar and a special locking clamp for attaching flex duct to the collar. Flex duct and other items are sold as accessory products.

What is the warranty of Abatement Portable Air Scrubbers?

All systems are covered by a comprehensive limited warranty to the original user against defects in materials and workmanship for a period of one year after date of purchase. This warranty excludes filters, which are consumable items that require ongoing replacement.

What is the estimated shipping time of Abatement PAS?

We do our best to keep all Abatement Portable Air Scrubbers in stock for same day or next day shipment when possible. Approximate shipping time within the continental United States is two to seven days. You will be notified immediately of the estimated delay should we experience extremely high demand and the system you order happens to be out of stock.

FAQs about Product Safety Certification

You really emphasize the fact that Abatement products are tested and certified by ETL, a Nationally recognized testing Laboratory (NRTL). What are the requirements?

In the USA, OSHA safety standards for general industry and construction and the National Electrical Code require testing and listing (certification) of electrical products to applicable standards. It is important to note that this testing must be performed on an electrical device even if the individual electrical components used in that device are all listed or approved. Testing must be done by an OSHA-recognized NRTL, such as UL (Underwriters Laboratories), ETL (Environmental Testing Laboratories) or CSA (Canadian Standards Association). In Canada, The Standards Council of Canada has adopted standards for the Canadian Electrical Code developed on its behalf by the Canadian Standards Association (CSA). Third party testing from a laboratory or other organization, not NRTL-certified is not acceptable, even if such testing is done to applicable standards.

Why is NRTL certification so important?

Unless a unit is properly tested, users have no way of knowing whether it is properly and safely designed to meet the requirements of the applicable electrical codes. It is wise to require written vendor verification that the products you purchase are NRTL certified.

Aren't all air filtration products properly certified?

No. Unfortunately, many of the air filtration systems sold to and used by contractors, healthcare facilities and others are not certified, especially negative air machines.

FAQs about HEPA Filters

Commonly Asked Questions about HEPA Filter Performance & Testing Requirements

What does the term HEPA mean?

HEPA is an acronym for "High-Efficiency Particulate Air" or "High-Efficiency Particulate Arrestance." This acronym refers to a filter that is manufactured, tested and certified to meet Institute of Environmental Sciences and Technology (IEST) construction, performance and certification standards as currently published in IEST RP-CC001.3.

How long have HEPA filters been in use?

The first HEPA filters were developed for the Atomic Energy Commission during World War II for use in facilities manufacturing components for the Manhattan (atomic bomb) project. These HEPA filters were originally designed to capture microscopic radioactive particles too small for effective removal by existing types of filters. HEPA filters used today are much more efficient and economical than the products made in the 1940's.

Where are HEPA filters used today?

HEPA filters are generally specified for applications where microscopic airborne particles or biopollutants could cause human health or product quality problems. Typical users include military, nuclear, pharmaceutical, electronics, biological and medical facilities.

What is it that makes HEPA filters so efficient?

The ultra-fine, glass-fiber medium captures microscopic particles that can easily pass through other filters by a combination of diffusion, interception and inertial impaction. To qualify as a Type A HEPA filter, the filter must capture at least 99.97% (9,997 out of 10,000) of particles 0.3 microns in size–about 300 times smaller than the diameter of a human hair, and 25 to 50 times smaller than we can see. To a HEPA filter, catching a one-micron particle (1/1,000,000 of a meter) is like stopping a cotton ball with a door screen.

Are filters this efficient really necessary for IAQ applications?

Laser particle counter measurements typically show that more than 99% of the particles suspended in indoor air are one micron (1/1,000,000 of a meter) or smaller in size. EPA calls these “lung-damaging” particles, because they can lodge deep in the lungs when inhaled. The ability of HEPA filters to capture particles this small is what sets them apart from other types of filters. Regulations developed by EPA, OSHA, CDC and other federal, state and local government agencies responsible for human health and IAQ issues specify HEPA filters for asbestos, lead and mold abatement, TB and SARS isolation rooms and healthcare renovation projects.

Are all filters made with HEPA filter media HEPA filters?

Manufacturing a filter with HEPA filter media does not mean that the filter itself meets true HEPA efficiency requirements. Serious filter leakage can go undetected if filters are not individually tested and certified at the end of the manufacturing process. Even the tiniest pinhole leaks in the media or breach of the seal between the media pack and the filter frame can cause the filter to fail IEST requirements. The testing requires very specific procedures using a thermally generated mono-dispersed aerosol and a laser particle counter. Some regulations also require field-testing by the user prior to going into service and periodically thereafter.

Why is the testing done with a 0.3-micron particle size test aerosol?

Filter efficiency studies have shown that 0.3-microns is the "Most Penetrating Particle Size (MPPS)" for HEPA filter media. Efficiency is typically greater than 99.97% against larger or smaller particle sizes. Particles larger than 0.3 microns are typically more easily trapped or intercepted, by the media. Smaller particles often lack sufficient mass to penetrate the media.

Is a "HEPA-Type" filter the same as a HEPA filter?

No. In fact, the differences are huge. According to the American Lung Association, filters classified as "HEPA-type" filters may capture as little as 55% of 0.3-micron particles (5,500 out of 10,000). By this definition, the true HEPA filter could be more than 1,800 times as efficient as the "HEPA-type" filter.

Does HEPA filter efficiency decrease as the filter gets dirty?

No. Unlike electronic air cleaners and other air purification technologies that experience substantial loss of efficiency as they become dirty, exactly the opposite typically happens with HEPA filters. In fact, the dirtier a HEPA filter gets, the more efficient it can become.

PRINCIPLES AND IMPORTANCE OF NEGATIVE PRESSURE CONTAINMENT

EFFECTIVE NEGATIVE PRESSURE PARTICLE CONTAINMENT USING ABATEMENT TECHNOLOGIES®PORTABLE AIR SCRUBBERS

Particles released into the air during facility construction, renovation, demolition and maintenance activities must be properly isolated and contained. Tiny particles and fungal spores are lightweight enough to remain aerosolized (suspended in the air) for hours, days or even weeks. The aerosolized particles can migrate into other areas of a facility on air currents and pose a potential threat to the health of sensitive patients. Larger particles can create housekeeping problems when they drop out of the air and settle on floors and other surfaces.

HOW NEGATIVE PRESSURE PARTICLE CONTAINMENT WORKS

Abatement Technologies HEPA-AIRE® and PREDATOR® series Portable Air Scrubbers (PAS) are designed to contain and capture indoor air particles and other contaminants and odors using a time-proven technique known as negative pressure particle containment. Effective negative pressure containment requires four main elements:

- Construction of a physical barrier around the work area to separate it from the rest of the facility.

- Sealing off any HVAC return air grills within the space to protect against particles being pulled into the HVAC system.

- Continuously pulling air within the area through a HEPA filtration device to reduce the number of airborne particles. Most job specifications require at least 6 air changes per hour (ACH), which means that the device must filter a volume of air equal to the air volume contained within the enclosed space 6 times per hour, or every 10 minutes.

- Exhausting at least 10% more cubic feet per minute of clean, HEPA-filtered air out of the space than is supplied into it to create and maintain negative pressure within that space. This helps ensure that any air leakage between the contained area and adjacent spaces will be “clean” air flowing in and not “dirty” air flowing out.

MODES OF OPERATION

State-of-the-art Portable Air Scrubbers from Abatement Technologies can be used in any of these modes of operation, depending on the air cleansing objectives and space limitations:

|

|

|

.

|

|

|

|

|

|

THE IMPORTANCE OF CONDUCTING A COMPREHENSIVE ICRA

CONDUCTING AN INFECTION CONTROL RISK ASSESSMENT (ICRA) IN A HEALTHCARE ORGANIZATION IS ESSENTIAL FOR MINIMIZING THE RISKS OF ACQUIRING AND TRANSMITTING INFECTIONS.

Conducting an Infection Control Risk Assessment (ICRA) in a healthcare organization is essential for minimizing the risks of acquiring and transmitting infections. The Joint Commission (TJC) has identified the need to conduct an ICRA when significant changes occur in the environment, community, or patient population as documented in the Infection Control (IC.01.03.01) and the Environment of Care (EC.02.06.05) standards. This is particularly true when conducting construction activities, especially demolition, where the risk of airborne dust and mold is the greatest and functionality of supporting utility systems can be jeopardized. Since the infection prevention program relies on the environment to provide controls for patient care, conducting an ICRA requires cooperation between Infection Prevention, Engineering, and Nursing.

The Center for Medicare and Medicaid Services (CMS) also requires an active program of prevention and control to avoid sources and transmission of infectious and communicable diseases (Condition of Participation 482.42). Therefore, an organization must have a program to conduct and assess risks, implement measures to control, mitigate, or eliminate identified risks, monitor control measures to determine their success, and institute modified or new measures to achieve that goal when necessary. The size, in square footage or cost, does not dictate the need or exclusion of the ICRA, but whether or not the activity will impact negatively on a patient is the criteria.

In addition, the Centers for Disease Control and Prevention (CDC) also identifies the need for conducting an ICRA during construction in the guidelines, “Recommendations for Environmental Infection Control in Healthcare Facilities Recommendations,” (Air Section II). It states that:

- Before the project gets underway, perform an ICRA to define the scope of the activity and the need for barrier measures

- Determine if immune-compromised patients may be at risk for exposure to fungal spores from dust generated during the project

- Develop a contingency plan to prevent such exposures

LINKS & ARTICLES

ARTICLES

Air Quality Sciences, Inc. - Ultrafine Particles: Why All the Concern About Something So Small?

Using Germicidal UV Disinfection - Alternative Methods for Using Germicidal UV Disinfection Lamps to Supplement HEPA Filtration

APIC State-of-the-Art Report: The Role of Infection Control During Construction in Health Care Facilities - APIC SOAR Construction 2000.pdf

Biological Contaminants in the HVAC System - Biological Contaminants in the HVAC System.pdf

LINKS

CDC Mold Site - www.cdc.gov/mold/default.htm

U.S. EPA Indoor Air Quality-Mold Site - www.epa.gov/iaq/molds/index.html

PROFESSIONAL ORGANIZATIONS AND ASSOCIATIONS

American Institute of Architects – www.aia.org

American Society for Healthcare Engineering - www.ashe.org

Association for Professionals in Infection Control and Epidemiology - www.apic.org

U.S. GOVERNMENT AGENCIES

Centers for Disease Control and Prevention – www.cdc.gov

Department of Homeland Security - www.dhs.gov

Health Resources and Services Administration (HRSA) - www.hrsa.gov

FOR CANADA

Canadian Standards Association: Infection Control During Construction or Renovation of Health Care Facilities - http://shop.csa.ca/en/canada/health-care-and-medical-devices-training/fundamentals-of-infection-control-during-construction/invt/500320002011

Construction-related Nosocomial Infections in Patients in Health Care Facilities - Canada Construction Related Guidelines.pdf

NRTL SAFETY CERTIFICATION

Abatement Technologies® HEPA-AIRE® and PREDATOR® Portable Air Scrubbers have been tested by a Nationally Recognized Testing Laboratory (NRTL), and carry the marks certifying that they comply with applicable OSHA and CSA electrical safety standards.

REQUIRED TESTING AND CERTIFICATION OF ELECTRICAL PRODUCTS

In the USA, OSHA safety standards for general industry and construction and the National Electrical Code require testing and listing (certification) of electrical products to applicable standards. It is important to note that this testing must be performed on an electrical device even if the individual electrical components used in that device are all listed or approved.

Testing must be done by an OSHA-recognized NRTL, such as UL (Underwriters Laboratories), ETL (Environmental Testing Laboratories), TÜV SÜD, or CSA (Canadian Standards Association). In Canada, The Standards Council of Canada has adopted standards for the Canadian Electrical Code developed on its behalf by the Canadian Standards Association (CSA). Third party testing from a laboratory or other organization, not NRTL-certified is not acceptable, even if such testing is done to applicable standards.

WHY IS NRTL CERTIFICATION IMPORTANT?

Unless a unit is properly tested, users have no way of knowing whether it is properly and safely designed to meet the requirements of the applicable electrical codes. It is wise to require written vendor verification that the products you purchase are NRTL certified.

AREN'T ALL AIR FILTRATION PRODUCTS PROPERLY CERTIFIED?

No. Unfortunately, many of the portable air scrubbers and air filtration systems sold to and used by contractors, healthcare facilities, and others are not certified. It is, therefore, impossible to know whether such products are safe or perhaps placing workers at risk.

PRODUCT SELECTION & APPLICATION ASSISTANCE

Contact Your Product Specialist from Abatement Technologies®

Abatement Technologies’ product specialists are here to answer technical questions and help you make the right product choices. Product specialists are available Monday-Friday, 8:00 a.m. - 5:30 p.m. Eastern time.

UNITED STATES CUSTOMERS

Customers in the U.S. can call toll-free at 800-634-9091 and ask to speak with a product specialist, or e-mail: iaqinfo@abatement.com

CANADIAN CUSTOMERS

Customers in Canada can call toll-free at 800-827-6443 and ask to speak with a product specialist, or e-mail: iaqinfo@abatement.ca

INTERNATIONAL CUSTOMERS

International customers can call 678-889-4200 and ask to speak with a product specialist, or e-mail:iaqinfo@abatement.com

ARE THE MOLDED PLASTIC FILTRATION UNITS YOU USE FIRE-SAFE?

PROPERLY DESIGNED MOLDED PLASTIC CABINETS CAN OFFER A NUMBER OF USER BENEFITS OVER FABRICATED METAL CABINETS FOR PORTABLE FILTRATION DEVICES.

They are typically lighter, and quality molded products and designs can be made more aesthetically pleasing. Quality molded products are more likely to maintain their appearance and shape over time, and less likely to damage objects they may bump against in use.

However, before buying a plastic molded product, users should look closely at whether that product has been properly tested and certified by a Nationally Recognized Tested Laboratory such as UL, ETL, or CSA, to ensure that it meets the UL94 flammability & flame spread requirements. If not, they could be risking that the device they are using – and possibly the job site – could go up in flames.

UL94 STANDARDS

Not all plastic resins meet the UL94 standard, and some of those that do not can be highly flammable. If such a cabinet is exposed to a flame or to excessive heat it can potentially erupt into a fireball very quickly. And, cabinet resin is not the only UL94 requirement. The standard includes a number of other specific design requirements to protect sensitive electrical components from possible exposure and degradation due to excessive heat or flames.

PREDATOR® MOLDED-CABINET PRODUCTS

Making a product that does meet the UL requirements may add cost; however, it also adds peace of mind, and it’s the right thing to do. That’s why the Predator® molded-cabinet products sold by Abatement Technologies have been tested and certified by a Nationally Recognized Testing Laboratory (NRTL) to meet UL94 requirements and carry safety certification labels.

Is it really worth it to your business to take on the risks of using molded products that don’t?