DUCTCLEANING

- DUCT CLEANING OVERVIEW

- CASHING IN ON IAQ

- ROTARY BRUSH SYSTEMS COMPARISON

- CONTRACTOR TESTIMONIALS

- FAQs

- VARIABLE FREQUENCY DRIVE IN ABATEMENT PORTABLE POWER VACUUMS

- NADCA HELPS CHRIS HANSEN & NBC DATELINE EXPOSE DUCT CLEANING SCAMS

- DUCT CLEANING PROCESS

- WHY AIRFLOW RATINGS CAN BE MISLEADING

- REASONS TO SELECT HEPA-AIRE®

DUCT CLEANING

Duct Cleaning Equipment, Specialty Tools & Accessories for the Professional Air Duct Cleaning Contractor

FROM THE INDUSTRY LEADER - ABATEMENT TECHNOLOGIES®

Abatement Technologies high-performance air duct cleaning equipment and specialty tools physically remove dirt, debris and other contaminants from commercial and residential ductwork systems. These exceptionally portable, HEPA-filtered air duct cleaning vacuums are designed to help duct cleaning professionals clean HVAC duct systems faster and more efficiently, and to help contractors develop profitable IAQ businesses.

CASHING IN ON IAQ

Increase profits with air duct cleaning services to an ever-growing Indoor Air Quality (IAQ) market opportunity

INCREASE PROFITS WITH THE INDUSTRY LEADER IN AIR DUCT CLEANING EQUIPMENT–ABATEMENT TECHNOLOGIES®

Residential and commercial air duct cleaning is one of the most lucrative business opportunities in the booming indoor air quality field, with excellent annual growth rates. Industry analysts expect this growth rate to continue through increased customer concern about IAQ in their homes and businesses.

A number of factors make air duct cleaning an attractive opportunity for service contractors:

- Produces excellent gross margins

- Can provide significant add-on revenues with existing customers

- Can generate new customers for other products and services

- Cleaning helps identify potential HVAC retrofit customers and close equipment retrofit deals

- Cleaning can generate new customers for other products and services

- Cleaning can generate revenue during slow times of the year

As the industry leader since 1990, Abatement Technologies has helped thousands of companies throughout the United States, Canada, and the world develop and grow successful air duct cleaning businesses. Companies using Abatement products have cleaned HVAC systems in millions of homes and commercial buildings and generated billions of dollars in duct cleaning revenues.

WHAT IS ‘SOURCE REMOVAL AND CAPTURE’ AIR DUCT CLEANING?

Studies have shown that even a small amount of dirt buildup on HVAC system components can significantly reduce HVAC efficiency and increase energy consumption. According to university research and industry standards, complete removal of dirt, debris and other contaminants from the air duct system is the most effective and acceptable cleaning and decontamination method for ductwork in both homes and commercial buildings.

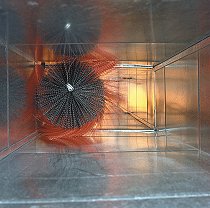

Dirty air duct.

Clean air duct after using Abatement source removal duct cleaning equipment.

Abatement Technologies duct cleaning method goes a step further by combining effective source removal with ‘source capture’:

- A specially designed compressor equipped with special agitation tools is used to loosen or dislodge dirt, debris and other contaminants from inner ductwork surfaces.

- A HEPA-AIRE portable vacuum system is taken right into the home or building and plugged into a standard 115-volt wall outlet. It combines the power needed to place the ductwork under negative pressure, and to pull out the contaminants, with a 3-stage filtration system that has the efficiency and capacity needed to capture them.

Because the HEPA-filtered air exhausted back into the indoor environment from the vacuum is cleaner than many hospital operating rooms, there is no need to pull huge amounts of heated or cooled air out of the building and exhaust it outside, as must be done with gasoline or diesel-powered equipment.

Learn more about Abatement’s HEPA-AIRE duct cleaning process.

GIVE YOUR COMPANY A COMPETITIVE EDGE WITH STATE-OF-THE-ART DUCT CLEANING EQUIPMENT

Abatement Technologies offers turnkey packages of high-performance air duct cleaning equipment and tools designed to deliver superior results in both residential and commercial HVAC ductwork. Key components of Abatement’s turnkey equipment packages include:

- HEPA-AIRE® PORTABLE POWER VACUUMS

- AIRE-SWEEP® PORTABLE AIR COMPRESSORS AND TOOLS

- DUCT-PRO® VIDEO INSPECTION SYSTEM

- SPECIALTY TOOLS & ACCESSORIES - For showing customers their ducts are dirty and comparing ‘before and after’ ductwork inspection.

Affordable Start-Up Packages

Affordable start-up packages of air duct cleaning equipment, tools, and professional marketing materials start around $6,000. High-quality marketing, training and sales support materials are also available to get you up and running quickly.

Contractors often find that Abatement Technologies’ duct cleaning systems deliver one of the best investment returns of any capital purchases. In fact, many contractors have been able to recoup their entire initial investment within the first few months of operation. There are even special equipment lease programs to spread the cost of the equipment over time.

Need More Information?

Abatement Technologies experienced and knowledgeable sales consultants are ready to assist you with product recommendations and procedures. Call us or Contact Ustoday for a complete package of information on how we can help your company add or improve a duct cleaning business.

ROTARY BRUSH SYSTEMS COMPARISON

READ THIS IF YOU ARE CONSIDERING A ROTARY BRUSH-TYPE SYSTEM

Thinking about adding duct cleaning to the services your business offers, or starting a new business? Confused by the types of equipment and methods available? Source removal duct cleaning is the only method recognized nationally as a duct-cleaning standard, and the generally accepted industry practice for more than 50 years.

On residential and small commercial jobs, this means placing an entire supply network or return network of the air conveyance system under negative pressure.

The relatively small number of duct cleaning companies in business between the 1950s until about 1990 mostly used truck-mounted vacuums & compressors for source removal cleaning to place the ductwork under negative pressure and operate high-velocity compressed air tools. Portable technology has dominated the industry since 1990 when Abatement Technologies first introduced this effective and more economical alternative to truck mounts. Several of the Abatement equipment packages include a rotary brush system or a Power Whip system that can be connected to the portable compressor for agitation of caked-on surface debris.

Another option available for residential duct cleaning companies is smaller-capacity vacuums, which look similar to a large, upright shop-type vacuum. Instead of power vacuums and compressors, these units use a 4-inch to 6-inch diameter rotary brush attached to the end of the hose to break contaminants loose. The brushes resemble those used on little shoe-shining machines seen in catalogues or in men’s rooms.

Unlike HEPA-AIRE equipment or truck mounts, rotary brush/shop vacuum systems do not have the ability to place the duct system under negative pressure, as required by nationally recognized standard-setting organizations.

Read what Professional Contractors have to say about Abatement Technologies® Air Duct Cleaning Equipment

“Awesome performance. An out-and-out winner! I've got almost 12,000 hours on my first HEPA-AIRE unit...and no problems. The best feature is that customers can see what you are taking out, and they are impressed by the high-tech appearance of the equipment."

– C.B., Cary, IL

“We just received our second HEPA-AIRE 2500 portable power vac… This new HEPA-AIRE 2500 really shows the engineering excellence of Abatement Technologies. (It is) the only choice for residential and light commercial work… We feel that the HEPA-AIRE 2500 is without a doubt the most professional looking and performing source removal equipment on the market today."

– B.R., Charleston, South Carolina

“The high power, ease of handling and overall quality workmanship of Abatement Technologies equipment are some of the reasons for our immediate success in the air duct cleaning field. (We) run our HEPA-AIRE 2500 machines nine hours a day, six days per week and have had no mechanical problems…Thank you for your workmanship and service in getting our

Air Duct Division off the ground and soaring.”

– C.M., Landsdowne, Pennsylvania

“It's a pleasure to do business with a company that treats its customers as we treat ours."

– H.L., Montgomery, AL

"I wanted to let you know that this complete system has performed well beyond our expectations.

We have had no problems with the equipment, and maintenance is a snap due to

the superior design… Be assured that when we purchase our next Duct Cleaning machine and accessories, it will be an Abatement Technologies system."

– J.M., Ontario, Canada

“After searching around the U.S. and Canada for several years and receiving numerous

data on duct cleaning systems, we can only thank God that we found out

about your systems. There is no comparison! After our purchase, we couldn’t be more

pleased with the performance of the equipment and are looking forward to purchasing more in the future! Even our customers, residential and commercial, are impressed with our equipment.”

– C.L., Waukegan, Illinois

“Our decision to offer duct cleaning to our customers has been a good one…

a terrific one in fact. It has become one of the most profitable areas of our business.

Beyond the excellent profits duct cleaning offers, it is also a source of new customers for the service and equipment replacement departments of our HVAC business.

Duct cleaning is the perfect complement to any HVAC contractor’s business…We couldn’t be more pleased with our selection of the Abatement Technologies duct cleaning equipment. The HEPA-AIRE 2500 lives up to its reputation as the leader in portable equipment.”

– J.G., Mobile, Alabama

“The introduction of the HEPA-AIRE 2500 by Abatement Technologies opened up another income opportunity for me. Combined with the Air Sweep Compressor System, it enabled my company to expand my duct cleaning business to the apartment and condominium market… The set-up is quick and easy. By unlatching each module, one man can transport the System 1 up or down a flight of stairs if no elevator is available. Best of all, HEPA filtration is 99% efficient at 1 micron for hospital grade exhaust air… Hats off to Abatement Technologies…….. They’ve come up with another winner!”

– L.P., Allentown, Pennsylvania

"Our company owns two of your HEPA-AIRE 2500 portable power vacs and duct cleaning equipment packages. To say that we are happy would be an understatement. We are totally pleased with your products and the way your company does business. Your products are terrific but it is the support after the sale that has really impressed us."

– N.C., Travelers Rest, South Carolina

“We have bought 5 HEPA-AIRE units since 1992. We were going to replace

the oldest one this year, but why should we? It still runs great.”

– M.C., Fairfax, VA

“I have used other brands of equipment before and I can’t believe the superior cleaning power of Abatement Technologies’ equipment. The first job I did I got 3 referrals.”

- R.H., Grand Island, NE

"The HEPA-AIRE 2500 vac has saved us a tremendous amount of money for replacement filters

(and it) has cut our costs back by almost 90%. We are also very happy with its portability.

We transport the HEPA-AIRE 2500 in a cargo van along with our compressor and all our other equipment and take it right to the furnace or air handler.

With its size and weight and built-in cart, we can usually get pretty close.

So far there have been zero maintenance problems… We have received very

good comments from our customers. They are impressed by it and say so."

– G.K., Atlanta, Georgia

"We just purchased a HEPA-AIRE 2500 last week and yesterday used it for the first time.

I must admit that, as a former truck user, I was more than a bit skeptical at first.

But after using the HEPA-AIRE 2500, I was amazed at the great job it does… Now, instead of just describing the type of dirt we remove, the HEPA-AIRE 2500 provides me a way to "show"

as well as "tell"…Congratulations on a job well done…"

– M.W., Stonewall, Louisiana

“This letter is to thank you for introducing our company to duct cleaning.

It has added a wonderful profit center to our business. It’s amazing how many of

our customers are interested in duct cleaning, especially when shown the inside of their ducts and what actually is in them… Again, I want to thank you and let you know how

pleased we are with our decision.

My only regret is not doing this ten years sooner.”

– A.G., Leesport, Pennsylvania

“We have been using Abatement Technologies products since 1992

and have found them to be of high quality and dependable performance. It was their

superior quality and expertise that attracted us in the first place.”

– L.S., British Columbia, Canada

"…we have just completed a big job and are extremely satisfied."

– T.D., Hertfordshire, United Kingdom

“Abatement Technology was chosen as the most efficient technology and convenient equipment.

Even during “crash tests”, when we tried to find the limits of your equipment in worse conditions,

your HEPA 2500 was the best equipment in every situation

(Nuclear, Research Laboratory, Hostels, Department stores, Factories, High speed trains, etc.).”

– T.J., Paris, France

“It is a pleasure to do business with companies that treat their customers as we treat ours. I would like to take this opportunity to say thank you for you and Abatement Technologies. We had received our fifth HEPA-AIRE 2500 this year. The most professional looking and performing source removal equipment make us become the champion air duct cleaning company in Hong Kong.”

– S.T., Aberdeen, Hong Kong

FAQS ABOUT EQUIPMENT FOR AIR DUCT CLEANING

Commonly Asked Questions about our Equipment and the Duct Cleaning Business

WHAT ABOUT TRAINING?

Abatement Technologies vacuums come with a comprehensive instructional DVD that covers the basic principles of source removal duct cleaning and applies those principles to many of the duct configurations encountered in the field. We can also refer you to some excellent hands-on training programs.

IS LEASING AVAILABLE?

Yes. We have found that the average monthly lease payment for a complete equipment package is equivalent to the revenue of one residential duct cleaning. Click for the lease rate calculator or contact Ryan Capital at 1-800-541-6370 for specific leasing information.

WHAT IS THE LEAD-TIME TO GET EQUIPMENT?

A large inventory of duct cleaning products is available for immediate shipment from our US and Canada warehouses. Well over 90% of all orders are shipped complete the day of the order.

WHERE DO I GET MY EQUIPMENT SERVICED?

Abatement HEPA-AIRE Vacuums are designed and engineered to be essentially maintenance-free, other than filter changes. In the highly unlikely event that a component of the control panel or the motor needs to be replaced, the modular design allows the user to make the change in a matter of minutes. AIRE-SWEEP Compressors are custom-manufactured for Abatement Technologies by a manufacturer with hundreds of authorized service centers located throughout the United States.

WHAT IS THE WARRANTY ON ABATEMENT TECHNOLOGIES EQUIPMENT?

Abatement Technologies is so confident in our product quality and workmanship that we offer a comprehensive 5-year limited warranty on all HEPA-AIRE Portable Power Vacuums. These are the longest warranties in the industry. The compressors have an excellent 2-year limited warranty.

HOW MANY COMPANIES USE ABATEMENT'S SOURCE REMOVAL DUCT CLEANING EQUIPMENT?

Abatement's duct cleaning products have been setting the industry standard since 1990. These products are used by more than 4,000 companies throughout all 50 US states, Canada and in more than 35 countries worldwide. It is estimated that these companies have cleaned the duct systems in more than 2 million homes and commercial buildings and have generated over $2.5 billion in duct cleaning revenues.

WHAT SHOULD BE CONSIDERED WHEN EVALUATING PERFORMANCE AND FUNCTIONALITY OF PORTABLE POWER VACUUMS FOR DUCT CLEANING?

The performance, quality, and reliability of this product are crucial to the quality of the work and ultimately the success of the business. Some of the most important factors include:

- Overall quality

- Airflow with all filters in place (rated by cfm)

- Vacuum static lift capability (rated by inches of w.c.)

- Filtration system efficiency and filter replacement costs

- Weight

- Overall size

- Portability

- Appearance

- Component ratings and quality

- Amenities such as corner bumpers, non-marking tires, stair climber, etc.

- Construction methods and materials

- Manufacturer's support and reputation

- Warranty

HOW LONG SHOULD A HEPA-AIRE PORTABLE POWER VAC LAST?

HEPA-AIRE systems are “over-engineered” to ensure many years of reliable operation. With reasonable care, a useful operating life of 10 years or more can be expected.

ARE THERE INDUSTRY STANDARDS OR METHODS THAT ALL DUCT CLEANING EQUIPMENT MANUFACTURERS USE WHEN MAKING AIRFLOW CLAIMS FOR THEIR PRODUCTS?

Unfortunately, there are no meaningful standards, and published claims and methods used are all over the map. Some manufacturers use the “free air” rating for the blower, or test airflow with the filters removed, methods which obviously indicate a much higher airflow than the equipment is capable of producing under normal operating conditions. A few companies have even begun to publish test results based on air velocity testing, which can be even more misleading. For example, the airflow of a machine that is rated at 3,000 fpm (feet per minute) with an 8" diameter outlet is only producing about 1,000 cfm. All of Abatement's performance claims are based on independent testing under real-life conditions with all filters in place.

HOW CAN I COMPARE AND EVALUATE THESE CLAIMS ACCURATELY?

Make sure that you are making “apples to apples” comparisons, and that all airflow testing has been done with all filters in place and by a reputable independent testing company. Be very skeptical of any self-testing, and always ask for documentation. Also, use common sense. Like anything else, if it seems too good to be true, it probably is.

WHY ARE A STRONG VACUUM AND COMPRESSED AIR NEEDED?

A high-powered compressor is essential for quality source removal duct cleaning. The AIRE-SWEEP nozzle is propelled throughout the entire duct system and used to continuously blast the ductwork with high-pressure blasts of air to dislodge debris and push it into the powerful air stream created by the power vacuum. With a sufficiently powerful vacuum, the debris will be pulled out of ductwork and into the vacuum's filtration system. This “push-pull” technique is the state-of-the-art method that is practiced by a vast majority of reputable duct cleaners.

WHY DO I NEED A TWO-STAGE COMPRESSOR WITH SUCH A HIGH PSI RATING?

An underpowered compressor can significantly increase job time and reduce cleaning quality. Compressors with a volume output of less than 16 cfm and pressure output of less than 175 psi are simply not powerful enough to effectively clean ductwork. Gasoline compressors with at least 8 horsepower engines or electric models with 5 horsepower electric motors are generally required. However, it is imperative that output specifications of the compressor–not engine horsepower–be considered when evaluating compressor performance.

CAN'T A ROTARY BRUSH INSIDE A SHOP-VAC HOSE BE USED INSTEAD OF THE POWER VAC AND COMPRESSOR?

These products have limited applications in small, round ducts that are easily accessible. However, real-life conditions often make it difficult if not impossible for “brush with a hose” products to produce acceptable results. In some cases, these products can potentially worsen the situation since the very low airflow (typically only 100-200 cfm at most) is not sufficient to pull contaminants dislodged by the brush out of the ductwork. The 3" to 4" diameter vacuum hose greatly limits their ability to handle the quantity, weight, and size of debris generally found in air ducts. In addition, the configuration of many duct systems makes it impossible to use a rotary brush or a hose without getting hung up on obstructions within the duct. This is particularly true of panned-in returns and other difficult to access ductwork locations.

WHAT IS THE MOST EFFECTIVE WAY TO MARKET A DUCT CLEANING SERVICE?

Promoting this service to your current customer base is generally the quickest and most productive way to get started. Abatement Technologies has an entire range of professionally produced marketing materials, including brochures, mailers, postcards, door hangers, ad slicks, DVDs, etc., to enable you to begin an effective and successful marketing program immediately.

FAQS ABOUT HEPA FILTERS

Commonly Asked Questions about HEPA Filter Performance & Testing Requirements

WHAT DOES THE TERM HEPA MEAN?

HEPA is an acronym for "High Efficiency Particulate Air" or "High Efficiency Particulate Arrestance." This acronym refers to a filter that is manufactured, tested and certified to meet Institute of Environmental Sciences and Technology (IEST) construction, performance and certification standards as currently published in IEST RP-CC001.3.

HOW LONG HAVE HEPA FILTERS BEEN IN USE?

The first HEPA filters were developed for the Atomic Energy Commission during World War II for use in facilities manufacturing components for the Manhattan (atomic bomb) project. These HEPA filters were originally designed to capture microscopic radioactive particles too small for effective removal by existing types of filters. HEPA filters used today are much more efficient and economical than the products made in the 1940's.

WHERE ARE HEPA FILTERS USED TODAY?

HEPA filters are generally specified for applications where microscopic airborne particles or biopollutants could cause human health or product quality problems. Typical users include military, nuclear, pharmaceutical, electronics, biological and medical facilities.

WHAT IS IT THAT MAKES HEPA FILTERS SO EFFICIENT?

The ultra-fine, glass-fiber medium captures microscopic particles that can easily pass through other filters by a combination of diffusion, interception and inertial impaction. To qualify as a Type A HEPA filter, the filter must capture at least 99.97% (9,997 out of 10,000) of particles 0.3 microns in size–about 300 times smaller than the diameter of a human hair, and 25 to 50 times smaller than we can see. To a HEPA filter, catching a one-micron particle (1/1,000,000 of a meter) is like stopping a cotton ball with a door screen.

ARE FILTERS THIS EFFICIENT REALLY NECESSARY FOR IAQ APPLICATIONS?

Laser particle counter measurements typically show that more than 99% of the particles suspended in indoor air are one micron (1/1,000,000 of a meter) or smaller in size. EPA calls these “lung-damaging” particles because they can lodge deep in the lungs when inhaled. The ability of HEPA filters to capture particles this small is what sets them apart from other types of filters. Regulations developed by EPA, OSHA, CDC and other federal, state and local government agencies responsible for human health and IAQ issues specify HEPA filters for asbestos, lead and mold abatement, TB and SARS isolation rooms and healthcare renovation projects.

ARE ALL FILTERS MADE WITH HEPA FILTER MEDIA HEPA FILTERS?

Manufacturing a filter with HEPA filter media does not mean that the filter itself meets true HEPA efficiency requirements. Serious filter leakage can go undetected if filters are not individually tested and certified at the end of the manufacturing process. Even the tiniest pinhole leaks in the media or breach of the seal between the media pack and the filter frame can cause the filter to fail IEST requirements. The testing requires very specific procedures using a thermally generated mono-dispersed aerosol and a laser particle counter. Some regulations also require field-testing by the user prior to going into service and periodically thereafter.

WHY IS THE TESTING DONE WITH A 0.3-MICRON PARTICLE SIZE TEST AEROSOL?

Filter efficiency studies have shown that 0.3-microns is the "Most Penetrating Particle Size (MPPS)" for HEPA filter media. Efficiency is typically greater than 99.97% against larger or smaller particle sizes. Particles larger than 0.3 microns are typically more easily trapped, or intercepted, by the media. Smaller particles often lack sufficient mass to penetrate the media.

IS A "HEPA-TYPE" FILTER THE SAME AS A HEPA FILTER?

No. In fact, the differences are huge. According to the American Lung Association, filters classified as "HEPA-type" filters may capture as little as 55% of 0.3-micron particles (5,500 out of 10,000). By this definition, the true HEPA filter could be more than 1,800 times as efficient as the "HEPA-type" filter.

DOES HEPA FILTER EFFICIENCY DECREASE AS THE FILTER GETS DIRTY?

No. Unlike electronic air cleaners and other air purification technologies that experience substantial loss of efficiency as they become dirty, exactly the opposite typically happens with HEPA filters. In fact, the dirtier a HEPA filter gets, the more efficient it can become.

VARIABLE FREQUENCY DRIVE IN ABATEMENT PORTABLE POWER VACUUMS

FAQS - The Benefits of the IntelliVac® Variable Frequency Drive (VFD) used in the H2500IV Vacuum from Abatement Technologies

Q: WHAT IS A VARIABLE FREQUENCY DRIVE?

A: A VFD, also known as a frequency inverter, is used to provide variable speed control for three-phase motors, as well as improved efficiency and performance.

Q: WHAT DOES THIS MEAN FOR A DUCT-CLEANING VACUUM?

A: If a basic VFD is used, the main benefit is a “soft start” feature, which allows the motor to come up to speed much more slowly. This feature can significantly reduce the amperage spike encountered when AC motors start up, minimizing problems with nuisance tripping of circuit breakers or fuses in the home. This problem can be especially prevalent with vacuums that also pull too much amperage for the available circuit.

Q: SOME OTHER VACUUMS ARE EQUIPPED WITH A VFD. WHAT MAKES THE INTELLIVAC DIFFERENT?

A: The H2500IV IntelliVac is equipped with a sophisticated, custom-designed VFD that does a lot more than merely soften the motor startup. This closed-loop controller continuously monitors a number of specific operating conditions and parameters, such as input voltage and filter loading. It then adjusts the motor and blower speed accordingly, to provide optimum performance under those conditions without over-amping the circuit. With the IntelliVac, peak operating speed of the high-efficiency, 3-phase motor and custom-designed, anodized-aluminum AT Gold blower can be increased from about 3,500rpm to about 4,800rpm.

Q: HOW DO THESE FEATURES BENEFIT THE DUCT CLEANER?

A: First of all, this feature increases maximum airflow capacity with clean filters by 15% to 20% or more. It also increases peak static capacity to over 7.5” water column, which is more than double some other vacuums. As a result, airflow losses related to factors such as filter loading or low voltage circuits can be cut by up to 75% or more. In addition, this added power throughout the filter-loading cycle reduces labor costs by allowing the duct cleaner to finish sooner. It also decreases replacement filter expenses, by substantially increasing the useful life of the filters. The bottom line is a better bottom line and satisfied customers.

Q: IS THE INTELLIVAC THE ONLY PRODUCT DESIGNED FOR MOTOR SPEED ADJUSTMENTS?

A: It is the only “smart” product designed to make these adjustments automatically, with no input from the operator. Needless to say, this feature is far more functional and user-friendly than a system designed for manual airflow adjustments, which typically involve increasing motor speed on a trial-and-error basis until the unit kicks a breaker or fuse.

Q: IS THIS PRODUCT PROVEN?

A: Absolutely. While the IntelliVac system has undergone significant upgrades and improvements over the years, thousands of units are in use, some for more than a decade.

NADCA HELPS CHRIS HANSEN & NBC DATELINE EXPOSE DUCT CLEANING SCAMS

NADCA EXPERT EXPOSES "SWITCH” MARKETING TACTICS, THEN USES ABATEMENT TECHNOLOGIES EQUIPMENT TO SHOW HOW TO CLEAN DUCTS PROPERLY!

For years now homeowners and legitimate duct cleaning companies all across the country have complained about companies that undermine the reputations of duct cleaning professionals who do the work properly by advertising “$49.95 whole house duct cleaning” teaser rates but almost always end up charging far more for work that is often poorly done. These companies particularly prey on senior citizens.

One of the segments on a special episode of the “Dateline Hansen Files” series featuring Chris Hansen aired by NBC TV nationally on Sunday January 30, 2011 NBC TV focused on these types of potentially misleading tactics. Two senior citizens allowed Dateline to plant hidden cameras in their Midwestern homes and contracted with local duct cleaners offering these advertised deals. The current president of the National Air Duct Cleaners Association (NADCA) was on hand as Dateline’s behind the cameras expert, observing and evaluating the work done.

According to the NADCA expert, the work done by the company hired for the first home was acceptable, but once in the home the technician convinced the homeowner that costly add-on services not included in the offer were necessary. These extra and overpriced services caused the final bill to ultimately balloon to more than 10 times the original teaser price.

SOURCE REMOVAL DUCT CLEANING PROCESS

How Abatement’s duct cleaning process removes caked-on dirt and debris from residential and commercial air ducts

SOURCE REMOVAL AND CAPTURE PROVIDES COMPLETE CLEANING AND DECONTAMINATION OF AIR DUCTS

The definition of source removal duct cleaning using the Abatement Technologies’ HEPA-AIRE cleaning process is as follows:

- Clean the air conveyance system using Abatement’s AIRE-SWEEP® Compressed Air Tools and DUCT-PRO® Mechanical Agitation Brush System to dislodge dirt and other contaminants from the ductwork and other HVAC components.

- Use a powerful Abatement HEPA-AIRE®, HEPA-filtered Portable Power Vacuum to place the section of the duct system being cleaned under negative pressure, pull dislodged contaminants out of the duct system and capture them.

A conventional HVAC duct system consists of a supply system of ducts to carry heated or cooled air from the furnace/air conditioner (air handler) to various parts of the home or building, and a return duct system to bring fresh air back to the air handler to be heated or cooled again. The supply network consists of main ducts, which carry air to smaller branch runs, which in turn carry air to the desired locations. The return network works in reverse.

STATE-OF-THE-ART SOURCE REMOVAL DUCT CLEANING PROCESS

The HEPA-AIRE process utilizes an Abatement HEPA-AIRE Portable Power Vac in tandem with a specially designed AIRE-SWEEP Portable Air Compressor and Agitation Tools for efficient state-of-the-art source removal duct cleaning. This method enables professional duct cleaners to remove contaminants from all parts of the duct system, regardless of location or type of duct. Yet it is simple to perform and requires only a limited amount of access holes. Here’s how it works:

- The supply and return networks are “zoned,” or separated, so they can be cleaned independently. This is typically done by removing the furnace filter, inserting it into a plastic bag and reinserting it into the furnace.

- An access hole is cut into the supply plenum and the flex duct from the HEPA-AIRE Vacuum inlet is connected to the plenum with a quick-connect attachment collar. The powerful vacuum creates high-velocity air movement within the supply ductwork to transport loosened dirt and contaminants out of the ductwork and into the vacuum's filtration/collection system.

- Each branch is cleaned separately starting with the branch farthest from the vacuum. The register and boot areas are blasted with compressed air from the AIRE-SWEEP Compressor using the special air booster gun to push any dirt or debris into the branch run.

- The branches are then cleaned by feeding the Forward AIRE-SWEEP Assembly down each branch run to push dirt and debris forward into the main run. The Reverse AIRE-SWEEP Assembly can also be used to clean branch runs if access at the main supply duct is available.

- Agitation devices such as the AIRE-SWEEP Power Brush, Duct Whip or Power Rod System are used when needed to dislodge caked-on debris from inside duct surfaces.

- The main duct run is then cleaned. First, one-inch diameter access holes must be cut into the duct every 25 feet. Then, the Agitation Devices and an AIRE-SWEEP Assembly are used to dislodge debris accumulated on surfaces. The loosened debris is pulled or pushed toward the HEPA-AIRE Portable Power Vacuum and captured in its multi-stage filtration/collection system.

- Once the supply side of the system has been completely cleaned, the return duct system is cleaned using the same method.

- The coil, motor and blower and blower compartment can be cleaned.

- Once the entire cleaning process is completed, all access holes are completely closed with the efficient CAPLUGS® and cover plates are installed over the access holes.

Learn about the advantages of Abatement Technologies’ HEPA-AIRE cleaning method compared to rotary brush-type systems.

NEED MORE INFORMATION?

Abatement Technologies experienced and knowledgeable sales consultants are ready to assist you with product recommendations and procedures. Call us or Contact Us today for a complete package of information on how we can help your company add or improve a duct cleaning business.

WHY AIRFLOW RATINGS CAN BE MISLEADING

NO INDUSTRY-STANDARD AIRFLOW RATING METHOD

There is no standardized method that manufacturers use to rate the airflow of their air filtration devices. Different methods can produce widely varying and often misleading results, and make direct comparisons between brands difficult if not impossible.

Comparing ‘Apples & Oranges’

Ratings The most overstated and inaccurate method used bases device airflow ratings on the AMCA “free air” blower rating, which is a test bench measurement of the airflow the blower can produce at various motor horsepower levels with no static resistance. Since actual peak airflow with the cabinet and filters in place is typically 50% to 80% lower, free air is essentially meaningless when it comes to rating the device itself.

Inlet or outlet readings with an air-straightening duct attached to reduce turbulence are far more accurate. This testing is generally done using a computing vane anemometer or pitot tube traverse to determine the average velocity (in feet per minute) and airflow (in cubic feet per minute) flowing through the air straightening duct. Attempting to measure airflow at non-laminar inlet and outlet openings is not recommended.

Peak Airflow Is Only Part Of The Story

Even when accurate, peak airflows can be misleading because they provide only a small part of the performance picture. It's often a mistake to automatically conclude that the performances of two devices are equal just because their peak airflows are similar. The airflow of all filtration devices drop off as resistance to airflow increases due to filter loading, external collars or flex duct. The magnitude and frequency of these losses; and therefore how frequently filters must be replaced to restore acceptable airflow levels can vary greatly.

Peak static capacity of the blower and filter dirt holding capacity are the main factors that determine 'real life' airflow and filter life. As a rule, a backward curved blower can move more air than a cheaper but less efficient squirrel-cage blower, due largely to its ability to operate at much higher 'tip speeds' and therefore overcome higher levels of resistance. This higher capacity, in turn, extends the useful life of the filters and can make a higher price but more efficient system far less costly to operate.

Build In A Sufficient Margin of Safety

To compensate for airflow losses, users should build in a safety margin when estimating how many units are required to provide a given number of ACH (air changes per hour). If the objective is 6 ACH, designing for 8 or 9 ACH at peak airflow should be more than adequate to ensure sufficient airflow throughout the filter loading cycle provided that the peak airflow rating is reasonably accurate.

HOW TO GROW YOUR BUSINESS USING ABATEMENT HEPA AIRE PORTABLE POWER VACUUMS

The differences in duct cleaning equipment from one product to another can be substantial. Unfortunately, companies entering the duct-cleaning business sometimes find this out too late–after they have purchased inferior equipment that doesn’t hold up or just doesn’t perform.

The following are reasons why Abatement Technologies has remained the duct cleaning industry leader for almost 15 years while others have come and gone. You’ll understand why our HEPA-AIRE vacuums are widely regarded as the finest in the industry and an excellent capital investment for your duct cleaning business.

INNOVATIVE TECHNOLOGY

HEPA-AIRE portable power vacuums were the first electric-powered, portable systems designed from the ground up specifically for source removal duct cleaning. Prior to the invention of these first models in 1990, air duct cleaning was done primarily using gasoline or diesel-powered truck-mounted vacuums, antiquated technology that dates back more than 50 years. The HEPA-AIRE equipment provided an effective alternative, and reduced the initial investment in equipment and ongoing maintenance and operating costs by up to 500%. Today, the HEPA-CARE method is the industry standard. Since 1990, more than 200 product improvements have reinforced Abatement’s leadership position, and reputation for exceptionally productive, cost-effective and user-friendly duct-cleaning vacuums.